Case Study 1:

Vibration Station

Challenge

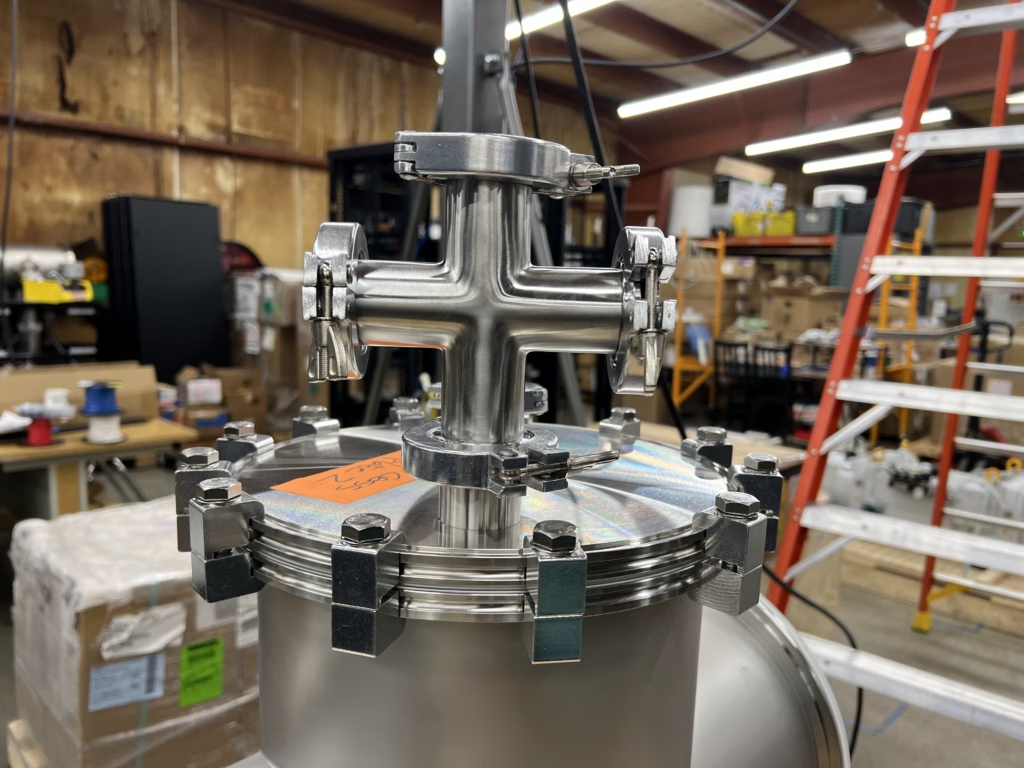

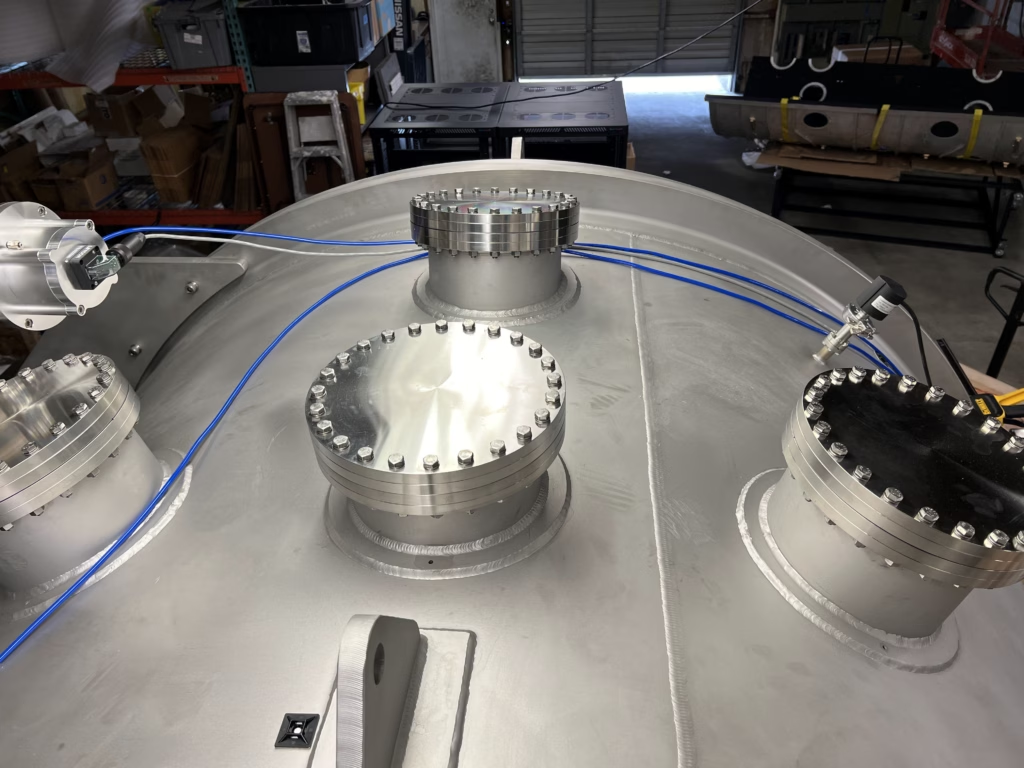

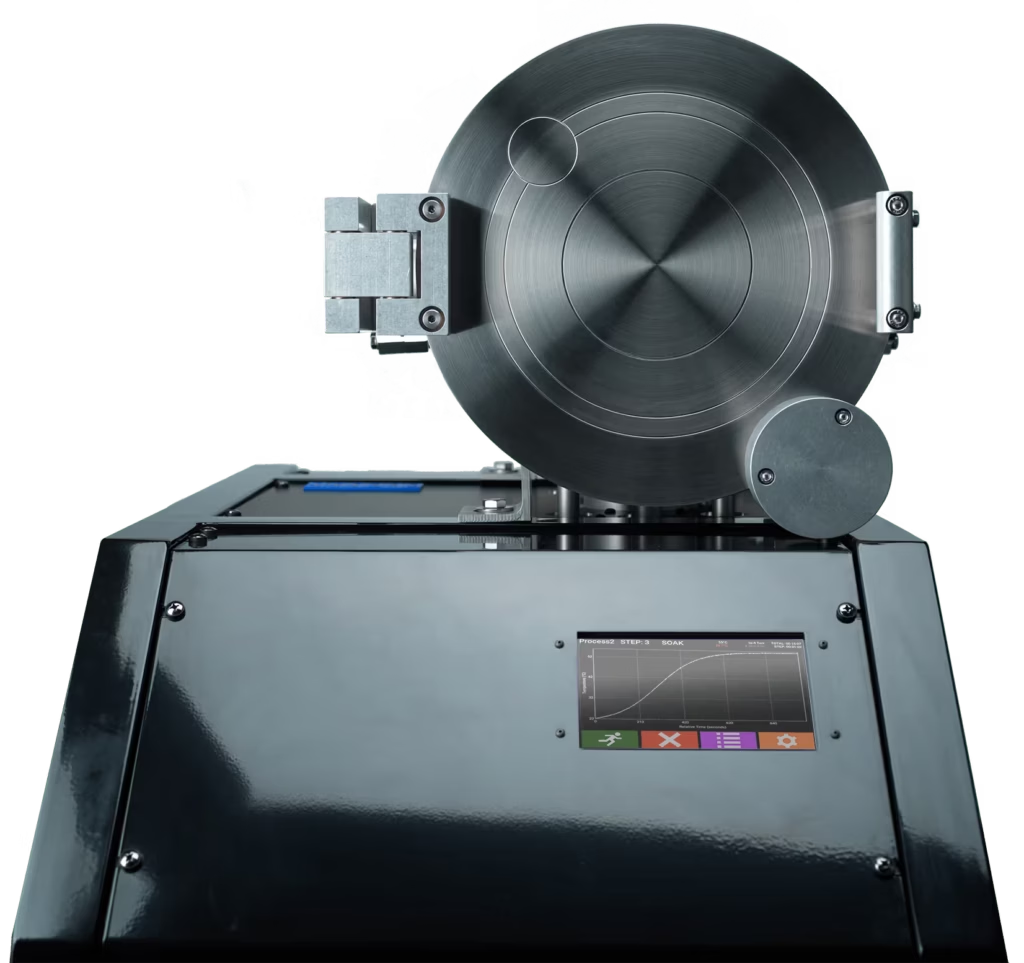

A nearby train line caused vibrations that disrupted sensitive optical experiments inside a thermal vacuum (TVAC) chamber.

Solution

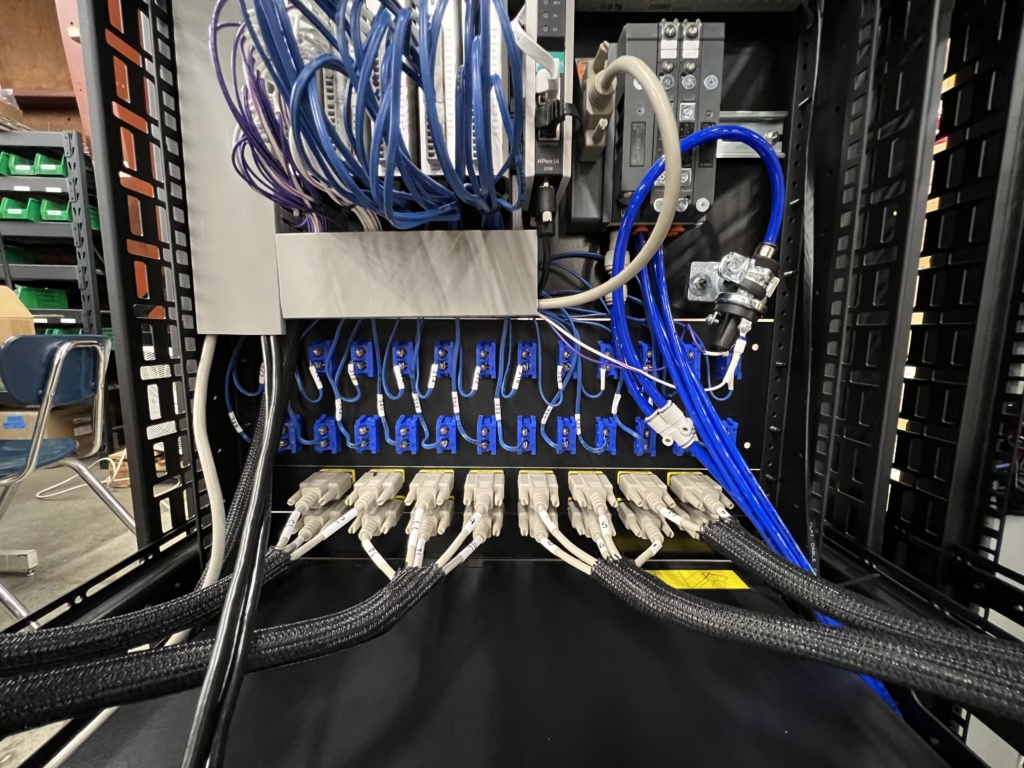

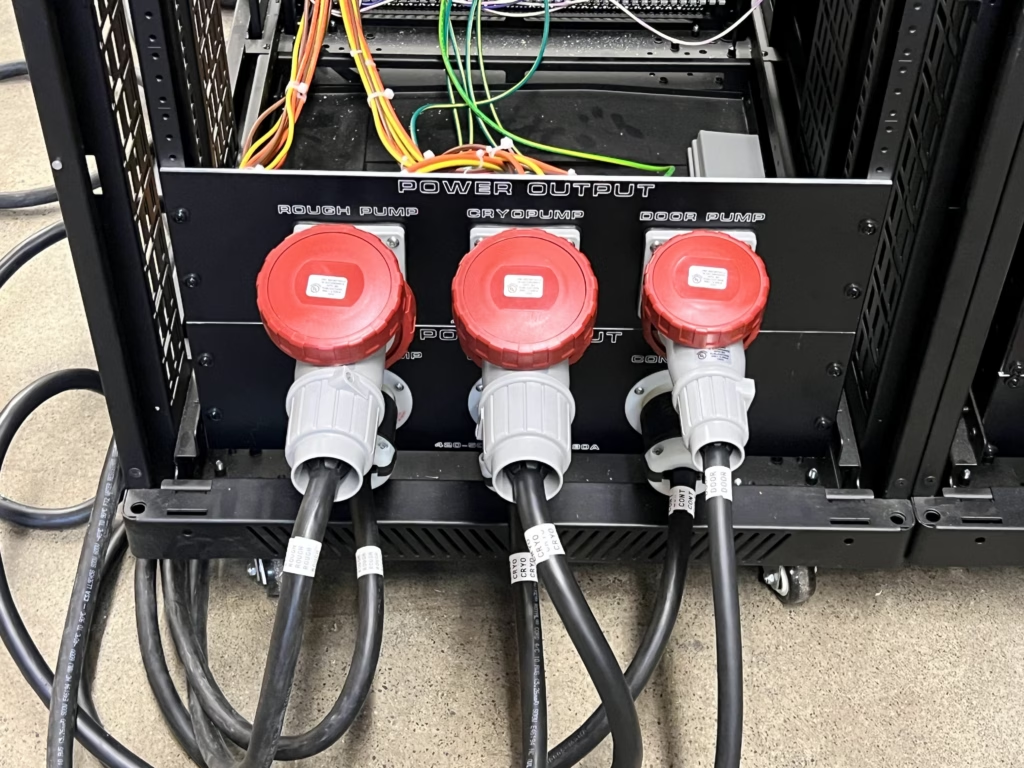

RVS designed a custom chamber with a vibration-isolated optical breadboard inside. By “floating” the optics platform within the chamber, we provided the university with a stable environment for thermal vacuum testing, without exceeding a university budget

Impact

Enabled reliable optical testing in a noisy environment, delivering performance and precision at an accessible cost.